Particle board: The Benefits of Using Environmentally Friendly Composite Wood

Technical Specifications

| Product Name |

Particle board |

| Environmental Class |

E1 |

| Specifications |

1220mm*2440mm |

| Thickness |

25mm |

| Density |

650-660kg/m³ |

| Standard |

BS EN312:2010 |

| Raw Material |

Rubber Tree |

| Product Name |

Particle board |

| Environmental Class |

E1 |

| Specifications |

1220mm*2440mm |

| Thickness |

15mm |

| Density |

650-660kg/m³ |

| Standard |

BS EN312:2010 |

| Raw Material |

Rubber Tree |

|

Product Name |

Particle board |

|

Environmental Class |

E1 |

|

Specifications |

1220mm*2440mm |

|

Thickness |

18mm |

|

Density |

650-660kg/m³ |

|

Standard |

BS EN312:2010 |

|

Raw Material |

Rubber Tree |

| Product Name |

Particle board |

| Environmental Class |

E0 |

| Specifications |

1220mm*2440mm |

| Thickness |

12mm |

| Density |

650-660kg/m³ |

| Standard |

BS EN312:2010 |

| Raw Material |

Rubber Tree |

| Product Name |

Particle board |

| Environmental Class |

E0 |

| Specifications |

1220mm*2440mm |

| Thickness |

15mm |

| Density |

650-660kg/m³ |

| Standard |

BS EN312:2010 |

| Raw Material |

Rubber Tree |

|

Product Name |

Particle board |

|

Environmental Class |

E0 |

|

Specifications |

1220mm*2440mm |

|

Thickness |

18mm |

|

Density |

650-660kg/m³ |

|

Standard |

BS EN312:2010 |

|

Raw Material |

Rubber Tree |

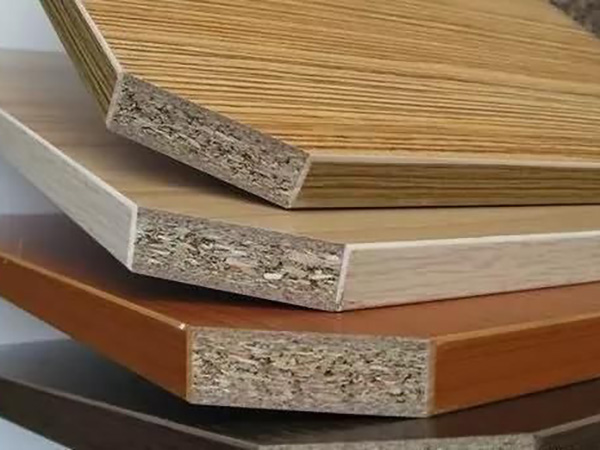

Product Usage

Mainly used for custom furniture,office furniture and other decorative substrates.

Product Advantages

1. Use rubber wood to produce good plane surface shape, uniform texture and good stability.

2. The surface is smooth and silky, matte and fine, to meet the requirements of the veneer.

3. Superior physical properties, uniform density, has the advantages of good static curvature strength, internal binding and etc.

4. The raw materials for the production of particle board are pure, easy to process in the subsequent use process, saving processing costs, and are welcomed by users.

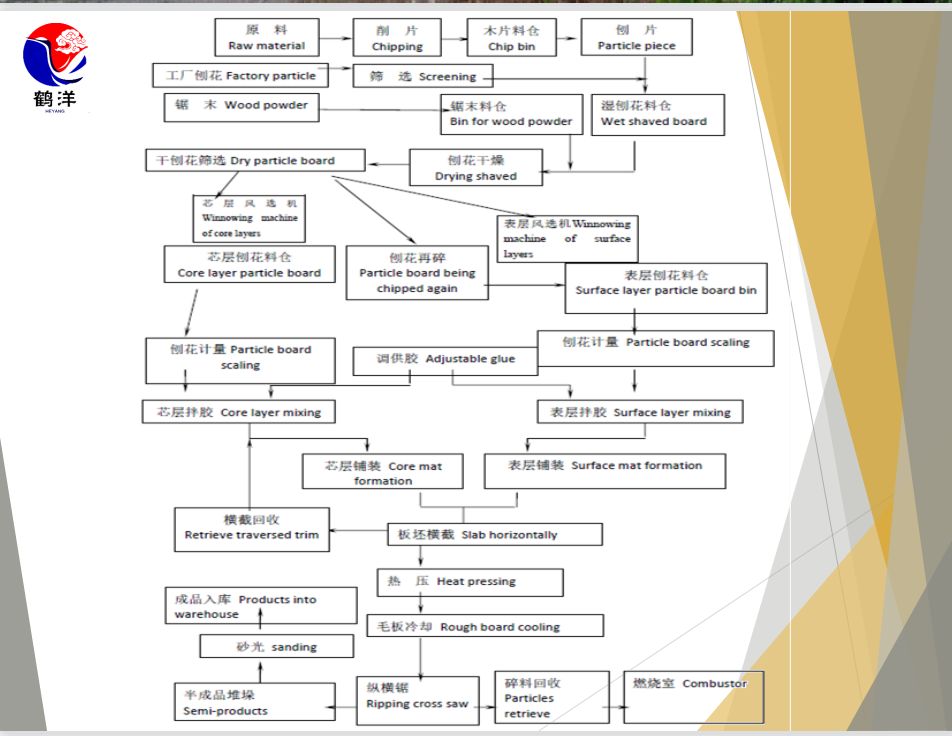

Production Process

Provide Services

1. Provide product testing report

2. Provide FSC certificate and CARB certificate

3. Substitute product samples and brochures

4. Provide technical process support

5. Customers enjoy product after-sales service

Product Description

Particle board is a versatile and cost-effective engineered wood product that serves as an excellent alternative to traditional solid wood boards. Made from compressing wood particles and adhesive resins under high pressure and heat, particle board offers exceptional strength and durability, making it ideal for various applications in the construction and furniture industries.

With its consistent and uniform composition, particle board provides a smooth and stable surface for a wide range of projects. It can be easily cut, drilled, and shaped to meet specific design requirements without compromising its structural integrity. The smooth surface also allows for easy finishing, painting, or laminating to achieve the desired aesthetic appeal.

Particle board's affordability makes it a popular choice for both residential and commercial projects. Its cost-effective nature allows for savings in material costs while still delivering reliable performance. Additionally, its uniform texture and consistency ensure consistent results throughout the entire board, eliminating the risk of weak spots or inconsistencies in the material.

Furthermore, particle board is an environmentally friendly option as it makes efficient use of wood resources that would otherwise go to waste. By utilizing wood particles and recycled wood fibers, particle board reduces the demand for solid wood boards, contributing to sustainable forestry practices.

Whether it's for cabinets, shelves, flooring, or other interior applications, particle board offers an economical solution without compromising on quality. Its versatility, durability, affordability, and eco-friendly attributes make it a popular choice for contractors, architects, and homeowners alike. Trust particle board to deliver reliable performance and exceptional value for your construction and furniture needs.